Project Overview

Glatfelter chose Carroll Daniel Engineering to provide engineering and procurement services for the installation of a new hardwood fiberline and oxygen delignification system. The new system enabled Glatfelter to meet stringent environmental regulations and improve overall product quality.

Maximizing Constructability

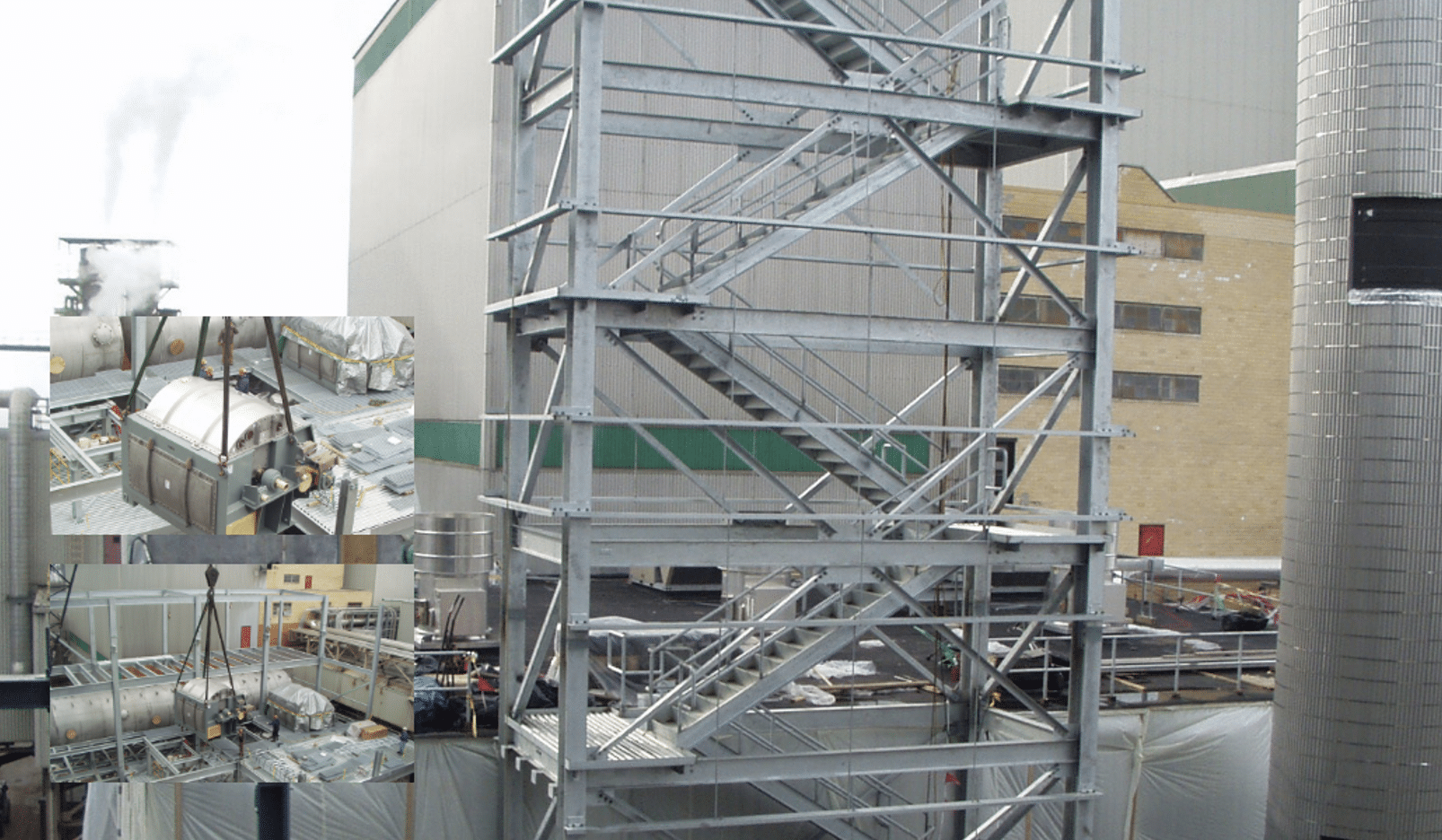

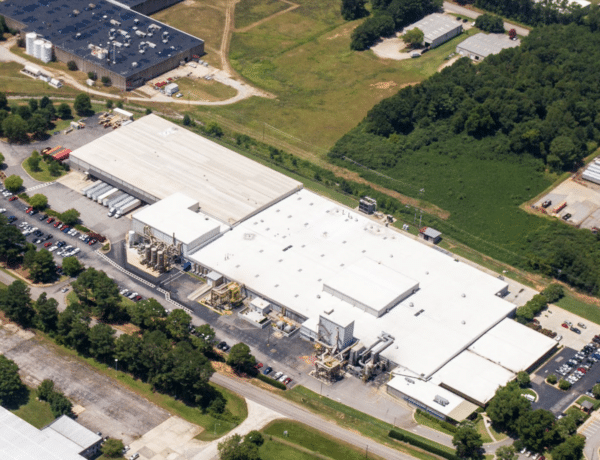

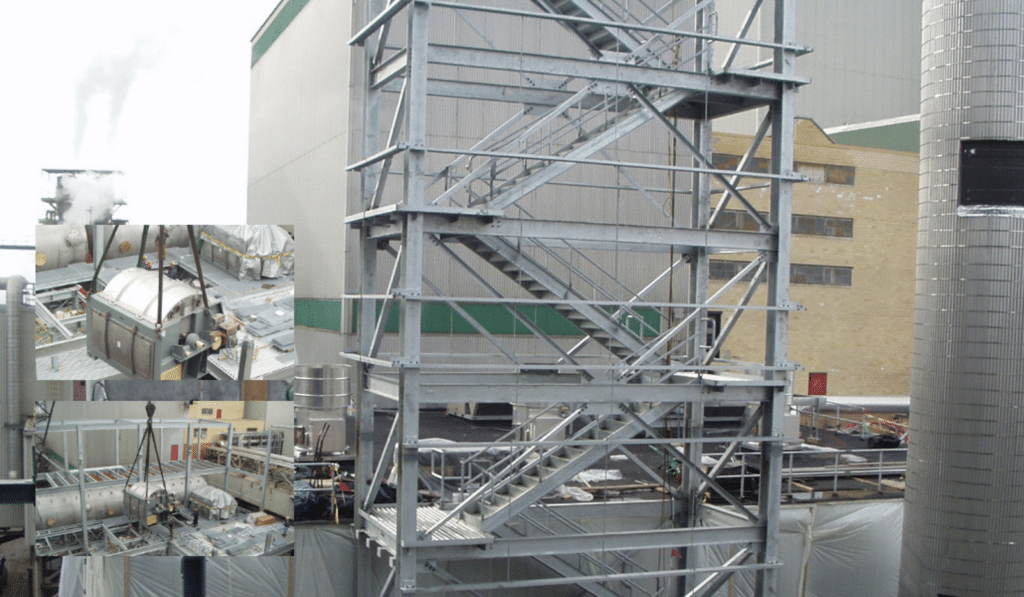

The 400-tons-per-day pulping system includes efficient washing and screening equipment and a single-stage, oxygen pre-bleaching system. The new process equipment is housed in a 10,000 SF, three story building. A new three-story office building was constructed as part of the project. The project is a study in constructability. The location and sizes of process equipment made it necessary to construct the structural frame of the building and equipment supports in an integrated manner with the equipment. Equipment was installed within the structure as it rose, saving cost and time.

Innovative Solutions

Tucked tightly between existing buildings, a rail spur and roadways, the installation required ongoing coordination to ensure coordination between construction lifts and other activities with mill raw material deliveries. The rail spur runs 20 feet from the building footprint and operates 24 hours per day. Work was scheduled around planned mill outages to sustain production operations. Executing this project within a tight operating space and with very large process equipment to install, took a great deal of thought in developing the 3D design model and scheduling. With input from the primary equipment vendor, subcontractors, other engineers and the Carroll Daniel Engineering team, these challenges were addressed very efficiently.