By The Numbers

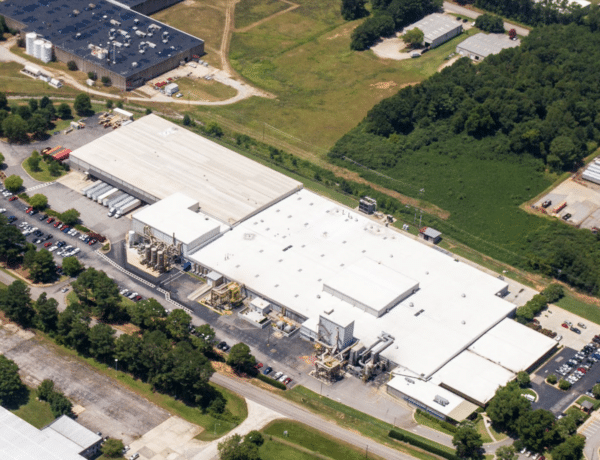

Huntsman’s synthetic iron-oxide pigments plant in Augusta, GA represented the first large scale investment in US pigment production in 2015. The plant produces 30,000 tons per year of red, yellow and black iron oxide based pigments. The process technology for this facility is similar to Huntsman’s manufacturing plant in Italy.

Project Details

Carroll Daniel Engineering provided engineering and procurement services for the 80-acre site and production facility. The project consisted of 1,927 tons of steel, 22,300 cubic yards of concrete, 21,000 feet control cable, and 67,000 feet of pipe.

Commitment to Quality

Quality was an important consideration on the project. Carroll Daniel Engineering’s quality program covered all aspects of the project. Carroll Daniel Engineering had a full time Quality Manager on-site that proactively worked with each subcontractor to ensure quality goals were met or exceeded. Carroll Daniel Engineering developed a surveillance and enforcement for all disciplines. The surveillance and non-conformity reports were insurance that the entire project was constructed to a very high standard. Since piping was a critical component of the project, a significant emphasis was placed on welding. The result was a weld reject rate below 5%.