Project Overview

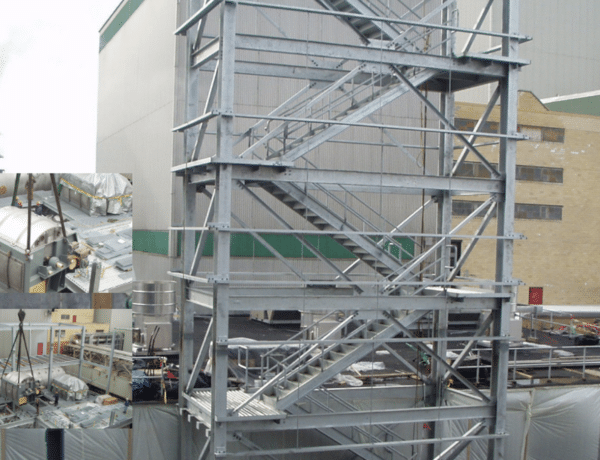

Carroll Daniel Engineering provided engineering design for a facility expansion in Kinston, NC to create new cGMP-compliant manufacturing spaces, including cleanroom manufacturing areas, micro and QC laboratories, a WFI water room, a new gowning/locker area and expanded central plant utilities.

Award-Winning Results

This project won an ISPE Facility of the Year Award (FOYA) for industry leading efforts to align primary components manufacturing process with current industry trends and standards.